Solar Thermal Cooling

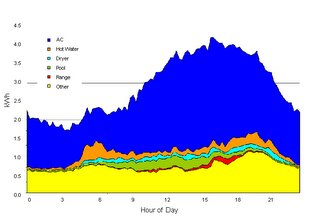

US peak electricity consumption occurs during the summer months when the demand for cooling is high and the efficiency of heat pumps drops with the higher ambient temperatures. Air conditioning constitutes approximately 15 % of annual US electricity consumption. However, the proportion of demand on peak days in hot states is in fact much higher.

Supplying peak power is very expensive for utilities because they must build the infrastructure to cover peak demand which otherwise sits around underutilized. As a potential means of peak shaving we can examine the use of solar power to provide cooling. In this case utilities could be persuaded to offer businesses and home owners incentives to install such systems because it would improve their bottom line. The introduction of net metering with variable electricity prices could also provide an impetus. In the current environment of fixed rate electricity the consumer has little reason to purchase such a system.

There are two practical approaches:

- Pair a photovoltaic array with a standard air conditioning unit.

- Pair a solar thermal collector with an aborption chiller.

A solar thermal system would use a collector to provide hot water for a single effect absorption chiller. Absorption chillers differ from common compression chillers in that cooling is driven by heat energy rather than mechanical energy. Aside from the plumping, several pieces of ancillary equipment are necessary including a controller, a pump, and a drain-back/expansion tank. Both systems are capable of providing hot water in addition to their cooling functions. For the PV system, a Heat Recovery Unit (HRU) would be used to pre-warm the water using waste heat from the heat pump.

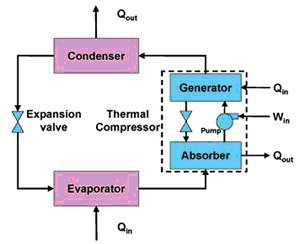

Some further explanation of absorption chillers is warranted given that they are relatively uncommon. An absorption chiller transfers thermal energy from the heat source to the heat sink through an absorbent fluid and a refrigerant. The absorption chiller accomplishes its refrigerative effect by absorbing and then releasing water vapor into and out of a lithium bromide or ammonia/water solution. The process begins as heat is applied at the generator and water vapor is driven off to a condenser. The cooled water vapor then passes through an expansion valve where the pressure reduces. The low-pressure water vapor then enters an evaporator, where ambient heat is added from a load and the actual cooling takes place. The heated, low-pressure vapor returns to the absorber, where it recombines with the lithium bromide and becomes a low-pressure liquid. This low-pressure solution is pumped to a higher pressure and into the generator to repeat the process.

The performance of air conditioning systems is expressed by their coefficient of performance (COP). COP determines how many units of cooling/heating you get for every unit of energy you put in. Because units move heat the COP can be in excess of one. A typical value for a air conditioning heat pump is about 3.5 compared to only 0.7 for a absorption chiller.

The COP of an absorption chiller is heavily dependant on the applied temperature. If the solar thermal system is only capable of producing tepid water it will not function effectively. For my analysis I will assume that the absorption chiller requires an input temperature of 85 oC compared to the typically 55 - 60 oC required for residential hot water. The obvious conclusion from this is that the cheap unglazed flat-plate solar thermal systems used to warm pool water aren't going to provide the temperatures we need. Instead, we have to move up to evacuated tube collectors.

Evacuated tube solar thermal collectors are sold by companies such as www.apricus-solar.com. They incorporate a number of improvements to increase their efficiency and maximum operating temperature:

- The absorber is insulated from the air by a vacuum. This greatly decreases convective losses to the wind.

- The absorber is coating with a spectrally selective surface. Such a surface has a high absorption coefficient (α ~ 0.9 – 0.95) in the visible wavelengths (550 nm) but a low emissivity coefficient (ε ~ 0.02 – 0.08) in the far infra-red (10,000 nm). This reduces radiation losses to a minimum.

- Heat is transferred from the absorber to the working fluid by means of a heat pipe. A heat pipe is filled with a partial pressure of water, such that it boils at 30 °C. When the water evaporates, it convects up to a heat exchanger where it condenses, transferring its energy to the working fluid. The effective thermal conductance is roughly 10,000 times that of a solid copper bar. The heat pipe also has a diode function, in that if it is not hot enough to evaporate the water, no convection will occur.

PV/Heat Pump: 0.125 * 3.5 = 0.44

Evacuated Solar-thermal/Absorption Chiller: 0.65 * 0.7 = 0.45

Amusingly they come out to being almost exactly the same. Assumably the inverter losses and parasitic heat losses are small and roughly equivalent. Presumably if you did an entropy analysis this would fall out quite naturally. Since the performance of each system is equivalent it is going to come down to cost.

If I size a 5000 W cooling system (for peak production at 1000 W/m2 insolation) for a home this is what I get:

| Photovoltaic | Solar Thermal | ||

| Component | Normalized Cost (US$/Wcool) | Component | Normalized Cost (US$/Wcool) |

| PV Array | 1.21 | Solar Collector | 1.99 |

| Heat Pump | 0.16 | Absorption Chiller | 0.32 |

| Inverter | 0.34 | Pump | 0.037 |

| | Controller | 0.079 | |

| Drain-Back Tank | 0.064 | ||

| Total | 1.71 | Total | 2.49 |

This is ignoring mounts, plumbing and wiring for both the solar thermal collector and PV array. As we can see it is the cost of the evacuated solar collector pushing it above the PV solution. The expensive nature of evacuated solar thermal tubes is probably due to both their complexity and their low production volumes. Since they don't appear to be superior in this role now it seems unlikely that they would ever be able to catch up.

PV / Heat Pump System

Photovoltaic Panel

Name: Sharp ND-167U1

Peak Power: 167 W at 1000 W/m2 insolation

Module Efficiency 12.6 %

Area: 1.33 m

List Price: US$ 688.97

Heat Pump Chiller

Type: LG model LWK0710WGL

Cooling Power: 2051 W (7000 btu)

Coefficient of Performance: 3.43

Electrical Consumption: 600 W

List Price: US$ 330

Inverter

Type: Grid inter-tie

Name: Solectria PVI 1800W

Continuous Power Input Rating: 1980 W

Recommended Max PV Array Power: 2200 W

Continuous Power Output Rating: 1800 W

List Price: US$ 1731.25

Solar Thermal / Absorption Chiller System

Solar Collector

Name: Apricus 30 Tube Collector

Gathering Area: 2.4 m2

Estimated Peak Power Generation: 1536 W

Absorption Chiller

Name: Yakaza WFC-10

Cooling Power: 10 tons

Coefficient of Performance: 0.7

List Price: unknown (generally 2x that of heat pump)

Controller

Name: Apricus Sentinel-Pro controller

List Price: US $395

Pump

Name: Grundfos Stainless UP15-18SU

Power: 1/25 hp

List Price: $184

Drain-back/Expansion Tank

Name: Alternate Energy Technologies DB-10

Capacity: 10 gallons

List Price: $322

Comments 0

EmoticonEmoticon